- Home

- About Us

-

Product & Tech Innovations

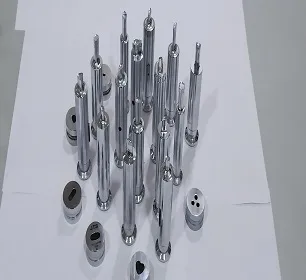

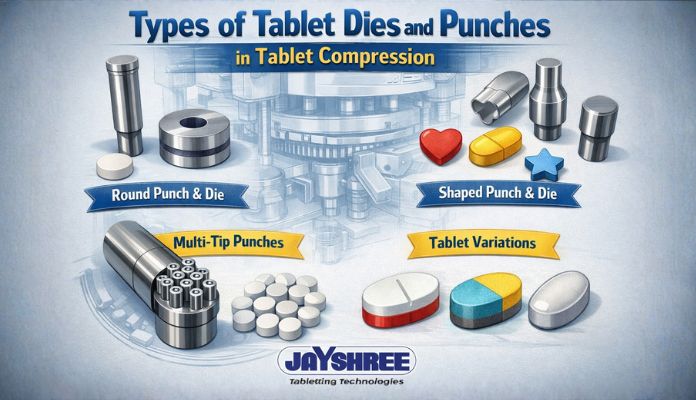

- Round Shape Toolings

- Shaped Toolings

- Bolous Toolings

- Special Toolings

- Confectionery Toolings

- Carbide and Ceramic Lined

- Multi Tip Toolings

- Punch polishing & Inspection Kits

- Sealed Groove Punches

- R & D Tablet Press

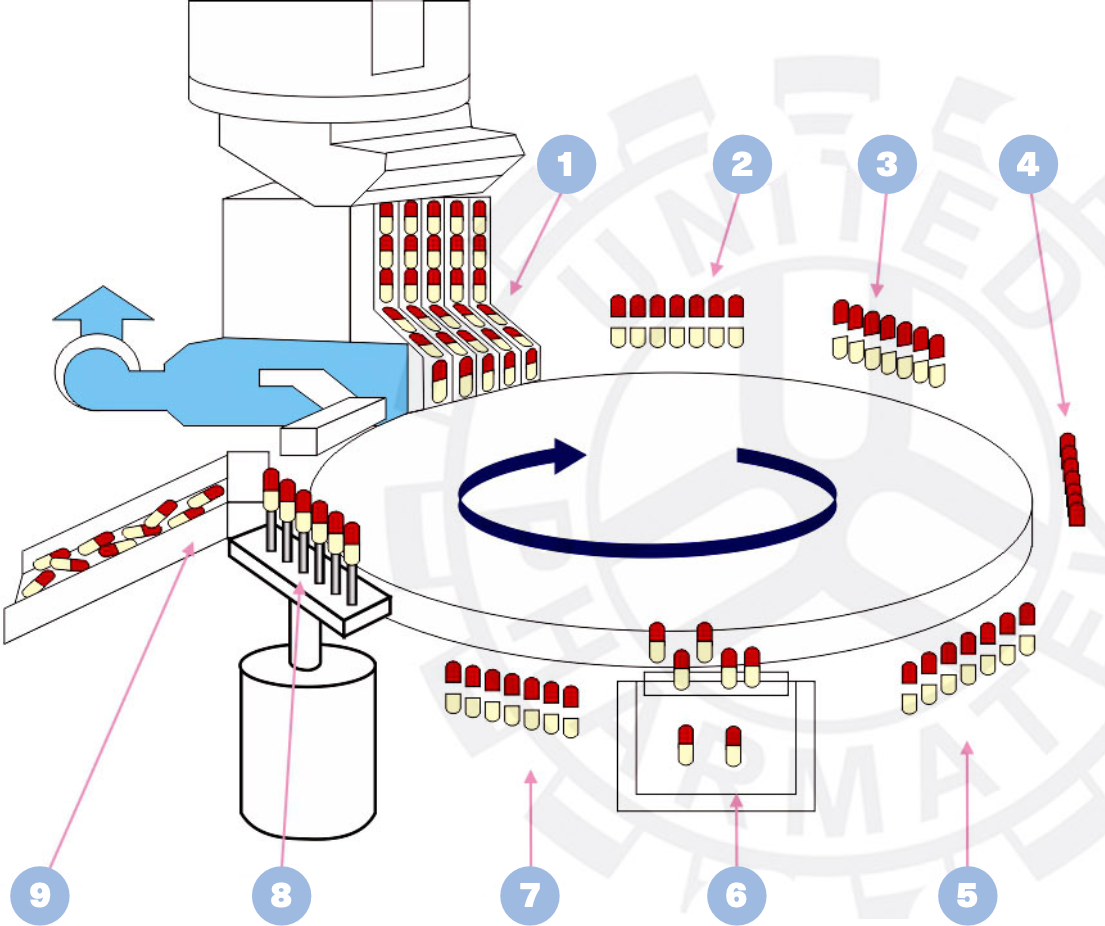

- Tablet Compression Machine

- Tablet De Duster

- Tablet & Capsule Inspection Machine

- Rapid Mixer Granulator

- Fluid Bed Dryer

- Octagonal Blender

- Multimill

- Roll Compactor

- Vacuum Conveying System

- Expertise & Supports

- International

- Clients

- Blog

- Contact Us